Ambu strives to minimise the impact of our products throughout their life cycle and to reduce our greenhouse gas emissions, energy consumption, manufacturing waste and hazardous material.

Circularity

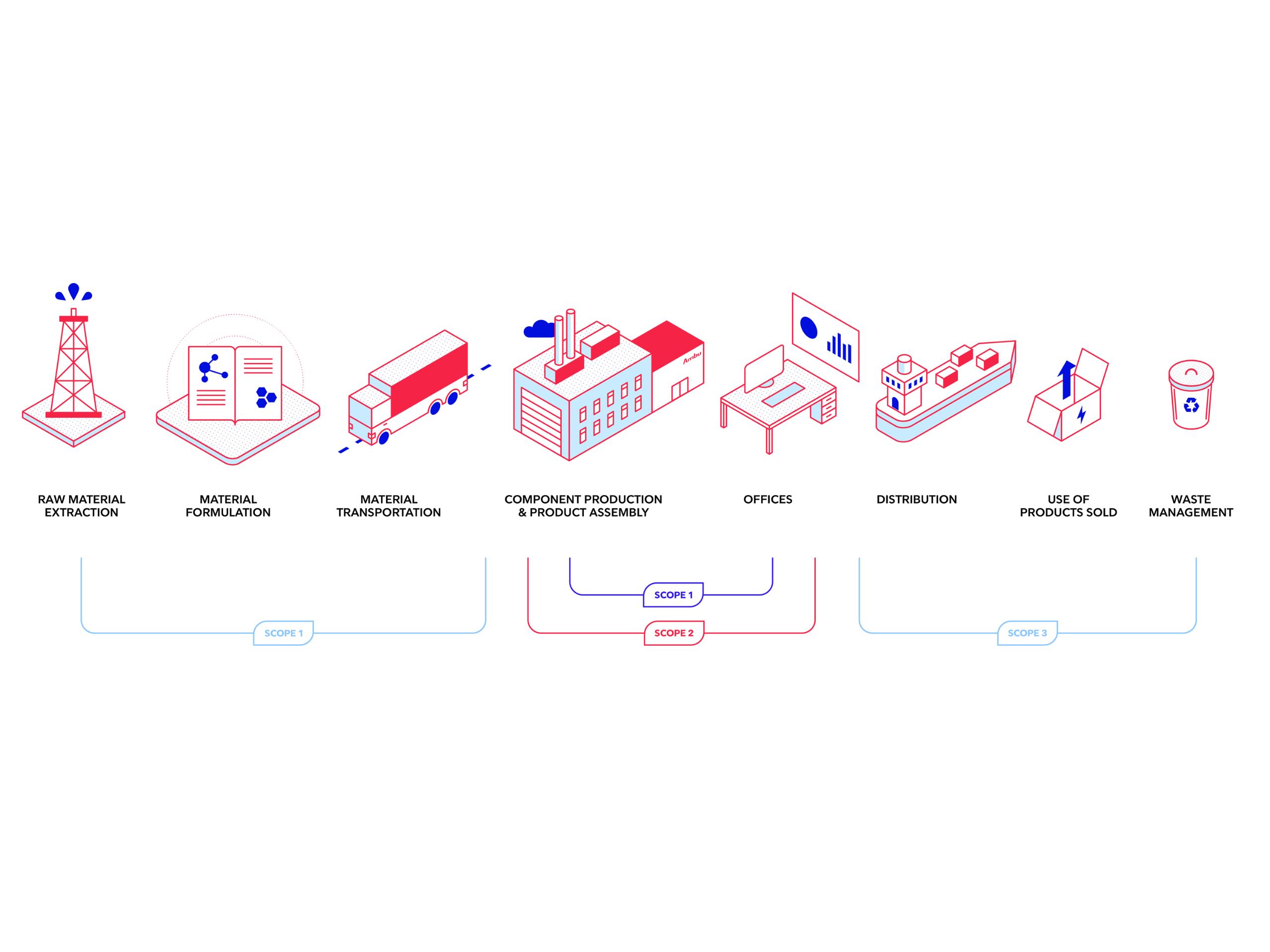

Ambu's single-use endoscopes and other products have an environmental impact throughout their life cycle – from raw material extraction until they are disposed of after use.

You can find information about how we endeavour to reduce the impact of our products throughout their life cycle in our description of our circular approach to products and packaging.

At Ambu, we strive to reduce the impact of our products by researching and investing in:

- The use of renewable materials, such as bio-based feedstock for plastic

- Solutions for take-back and recycling

Ambitions and targets for circularity

We strive to minimise the environmental impact of our products wherever possible throughout their life cycle, in order to contribute to the circular economy. We have set a number of goals to be completed by 2025 that will help us achieve these targets:

- Bioplastics in all currently marketed endoscopes handles by end of 2024

- Primary packaging for high volume products made from bioplastics

- Recycling offering in all our focus markets

Explore our progress on our environment, social and governance priorities in our latest Annual Report.

Energy Consumption

As part of our strategy to approach net-zero emissions, our production sites and headquarters work rigorously to identify and act on opportunities to reduce emissions through energy efficiency measures.

Through energy monitoring and audits, our sites are gaining a better understanding of where the biggest energy consumption is taking place. Furthermore, we are increasingly sharing learnings across our sites to help each other bring down local energy consumption and emissions.

Ambitions and targets for energy consumption

We aim to reduce total energy consumption and increase energy efficiency as well as the share of renewable energy in our operations.

You can explore our progress on our environment, social and governance priorities in our latest Annual Report.

Manufacturing waste and hazardous materials

At Ambu, we believe that waste has the potential to become a resource once an appropriate method has been found. By measuring waste amounts, each production site gains a better understanding of its waste streams and upcycling opportunities.

While we cannot totally avoid creating waste at our sites, we are working hard to ensure that as much waste as possible is used to create value further down the value chain.

Our sites are sorting more and more waste into different fractions in order to increase the amount that is recycled. Through partnerships and local initiatives, we are working on ways to increase the amounts of waste that can be reused or converted into either energy, fertilizers or components of new materials.

Ambitions and targets for handling manufacturing waste and hazardous materials

Reduce waste where possible and recycle according to the waste hierarchy, in order to minimize use of virgin resources and thereby reduce our impact on the environment and climate.

Explore our progress on our environment, social and governance priorities in our latest Annual Report.